Stainless Steel Pipe/Tube Polishing Machine produced in Chinese factories is well known by its most economic cost, and effective polishing and buffing surface finish. The polishing speed can reach to 35meter/min.

However, dust caused during polishing process is the very necessary issue to be solved at the beginning even before start the machine. Because dust not only dirty your workshop, most important, it will cause health danger for the operators.

Below we just introduce how some Chinese tube manufactures solve the dust collecting problem.

1. Principle

The dust collection system can only be built on site according to customer factory design & arrangement. Its main principle is as below:

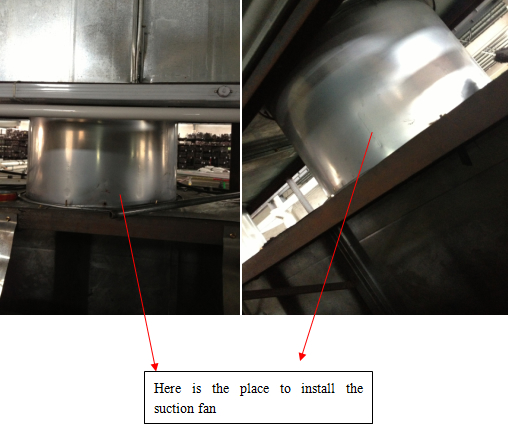

1) by using suction fan to absorb the dust caused during the polishing process.

2) Using the channel made of galvanized iron plate to collect dust from every suction fan.(The channel is empty, no other device)

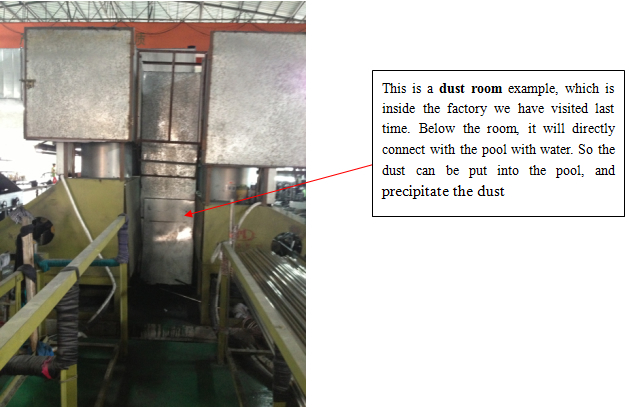

3) With the help of the suction fan, the dust will be blow inside the water pool which is prepared under the dust collection room

4) By using the water pool to precipitate the dust

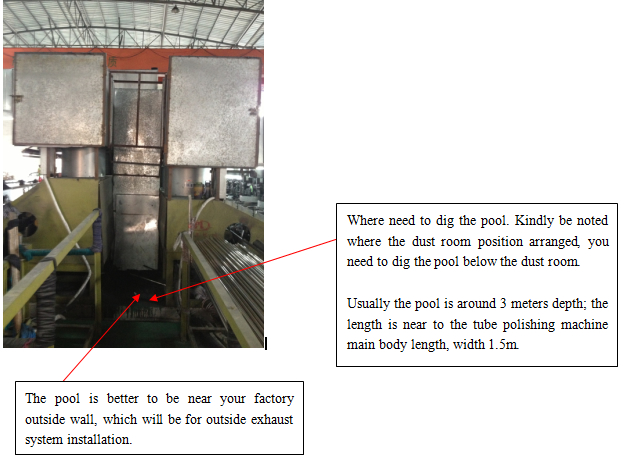

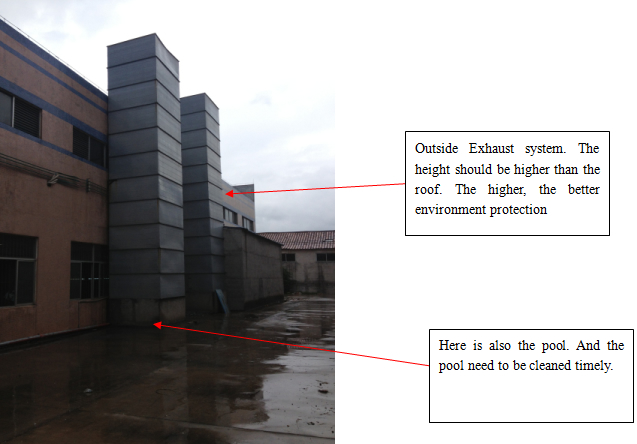

5) Building an outside exhaust system to let the air go.

2. dust collection system with photo explanation

1) where to install the suction fan

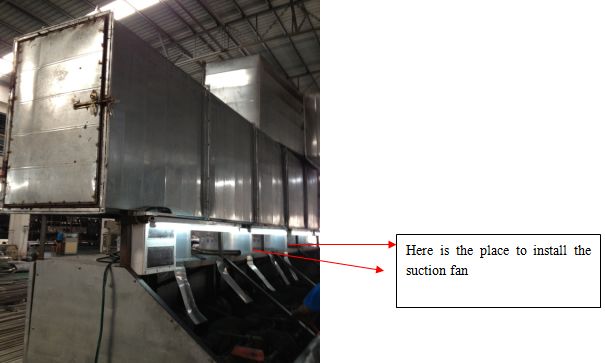

3) Build the channel. Material used is galvanized iron plate.

The plate need to be welded together to make a sealed space/shape.

Inside the channel, it's empty without any device.

4) collect the dust from all suction fan in a room

5) Dig a pool under the dust room to precipitate the dust.

6) Building an outside exhaust system to let the air go.

I hope above explanation will be of help of your understanding.